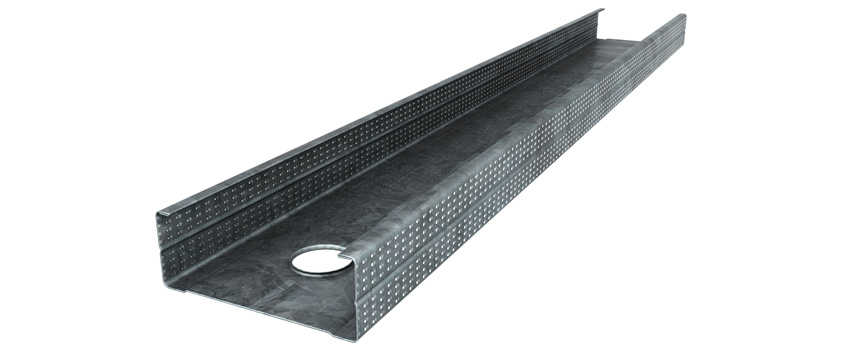

Rondo’s Stud & Track system provides superior time and safety features as standard, so you can get on with the job.

First, it’s durable, next it’s practical and finally it’s lightweight. These are just a few reasons why the Rondo Steel Stud Drywall Framing System is the best system on the market for internal plasterboard walls and specific external wall systems.

The availability of various sizes, complimentary components such as noggin tracks, curved tracks and special cleats ensure Rondo’s Stud & Track Wall System is available to suit almost all situations.

Our 0.50, 0.70 & 0.75BMT Wall and Deflection Head Tracks as well as 0.50 & 0.55BMT Wall Studs are designed to not only perform better, but their hemmed edges also improve safety on site.

Rondo Stud and Track Wall Systems are also available to suit almost any situation – making them incredibly versatile so quite simply, you can’t lose.

So, what is different about our stud & track system that makes it so good?

Well, you’ve probably noticed that not all stud & track profiles on the market today are hemmed. Rondo’s range of hemmed Stud & Track products were the first.

In 2009, Rondo became the first Australian manufacturer to add a hem to our wall studs for safer handling and a stiffer, stronger profile.

To this day, no other manufacturer has been able to reproduce our roll formed design.

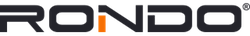

- The hemmed return lip

Majority of Stud and Track are hemmed for safety and increased strength.

Better technology and Rondo’s experience enabled us to produce a hemmed return lip to the flange of the Stud or Track, which increases its stiffness, reduces unwanted rotation, so is ultimately safer as there are no sharp protruding edges.

- The Stud Flange

The Rondo Hemmed Stud includes flanged service holes and is entirely compatible with existing wall tracks and studs, therefore, can be used in situations where bonding into existing framing is necessary. Additionally, they include a central vertical rib which assists the lining up of the board when fixing.

- Deeper knurling

Provides superior screw location and retention. The mountain knurling along the flanges of the studs are designed to provide the screw point with a positive location during fitting of the lining board.

- Efficient Stud locking system

Our Studs lock perfectly into each other creating the best boxed stud profile available in the market today.

- Friction Fit

Track sections provide a friction fit for the Studs, which not only holds the studs in place until the lining board is fitted, but also provides a slip joint to allow for movement in the structure.

You will benefit from using our Stud and Track System in a wide range of applications including:

- Non-load bearing partition walls

- Load bearing walls by design

- Steel Stud Ceiling Systems

- Windows and Door Jambs

- Non-Fire Rated Systems & Fire-Rated Systems

- Acoustic Wall Systems by design

- External Wall Systems by design

- Light Weight Floor Joists

- Bulkheads

In fact, if you find yourself in a situation where the Stud length is shorter than required, then the 0.50, 0.55 and 0.75BMT Studs may be spliced to extend their overall length…or you can order your Studs to be produced in special lengths, keeping in mind that minimum order quantities and lead times apply.

Our Studs can also be or you can order your Studs to be produced in special lengths…keeping in mind that minimum order quantities and lead times apply.

So, get on the right track by visiting the Stud & Track section of our website, downloading a copy of our Professional Design Manual or, if you would like a quick demonstration of best practice watch our YouTube tutorial, “How to install Rondo Steel Stud and Track Wall Framing System.”

(Psst! Don’t worry, if Stud & Track isn’t what you need feel free to check out some of our other wall systems that may be more suitable).